Suffolk County’s Premier Walkway Installer

Experience exceptional outdoor transformations with our skilled Paver Construction team. Elevate your space with our professional paver walkway installation near me services. Transform your patio today! See a video below for a visual example.

Affordablepatio.com has built an outstanding reputation across Long Island, which has led us to become a top masonry contractor. Over the last 15 years, we have installed thousands of walkways across Suffolk County. We specialize in installing paver walkways. Above all, our dedicated Walkway Installers ensure a flawless result for your project. To further emphasize our dedication and professionalism, we have been granted the title of being a Preferred and Certified Cambridge Paving Stone Installer.

Our team prides itself on educating all of our customers, which we have found eliminates any stress that may arise when starting a project like this. Accordingly, if you’re searching for a paver walkway installation near me, we’re here to guide you through every step. To make this process even easier for you, everything that you need to know about your new walkway installation can be found below. Also, we’re committed to providing you with an exceptional experience from start to finish.

How Much Does a Paver Walkway Cost?

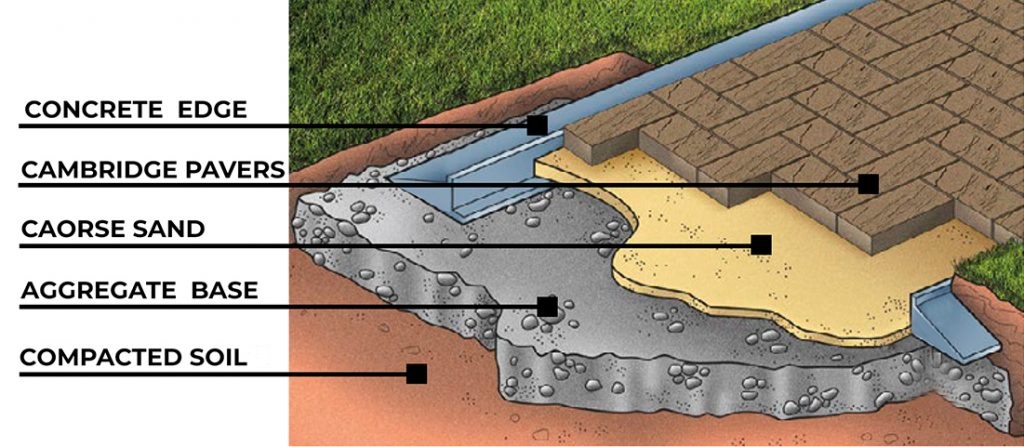

What's under our Walkways

We install our walkways to manufacture specs. 4-6” of crushed concrete base, compacted with a gas-powered plate compactor followed by a ¼” of fine mason sand for the leveling process. Next step is paver installation, concreting edges in, and lastly poly sanding the joints of your new walkway. (More detailed info provided below)

Although the installation process may seem complicated, rest assured that our expert Walkway Installers handle every detail. Certainly, we ensure each element is meticulously executed for a durable and stunning walkway.

Setting Heights Based off the Grade of Your Property

The first step to do a paver walkway installation is evaluating the level of your property. This is the most important step in figuring out the height of your new Paver Construction project. This will determine everything else moving forward. Concurrently, understanding the elevation is crucial. Once we know our starting height, we will add “pitch” to the pavers, we like to add 1.5” every 10ft pitched away from your home. This will ensure proper water run-off and make sure the walkway does not feel like a ramp. As much as aesthetics matter, functionality is equally prioritized.

Excavation, Removal of Soil or Debris in the Area of Your New Paver Project

Setting Up Forms & Installing Subbase

While one crew is working, other crew members will start to set up forms, these wood forms are used to keep our sub-base at the level we need it. Once the forms are in place and temporarily secured, we start to fill the area with RCA. Recycled concrete aggregate, is what we use as a subbase for all residential. Paver walkway installation is only necessary around new pools and driveways. The RCA is installed in “lifts,” meaning we fill the area with 2-3” of base, compact it, and then repeat until we reach the top of our forms. As a result, our Paver Construction project achieves a strong foundation. Once we have achieved a satisfied amount of subbase, it is time to add fine sand. The sand will get spread over our RCA subbase, tamped, and then screeded out to a smooth finish. Since the pavers are manufactured with a 1/16th of an inch error from the molds, the sand will allow us to get the top of the pavers to a leveled surface. This meticulous process ensures precision as well as aesthetics.

Setting Up to Lay Pavers

Once the sand is ready we can set up our square lines. When you lay pavers, the joints in between each paver create bond lines, when setting up the walkway we want to ensure it is “square” with your home or any other designated and stationary structure in that area. This is proper construction edicate and most visually appealing to the eye. Our team is trained to lay pavers first and borders after.

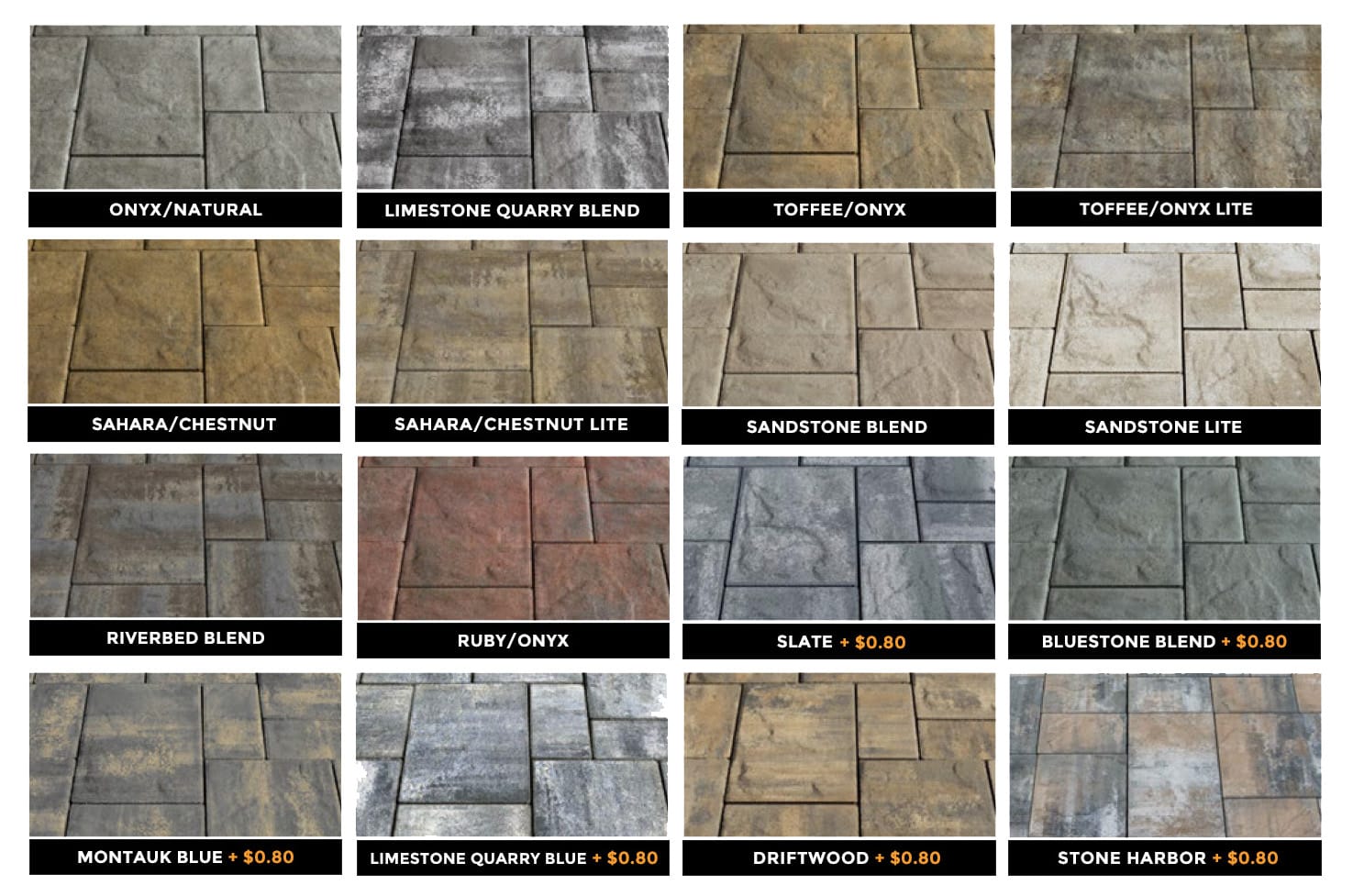

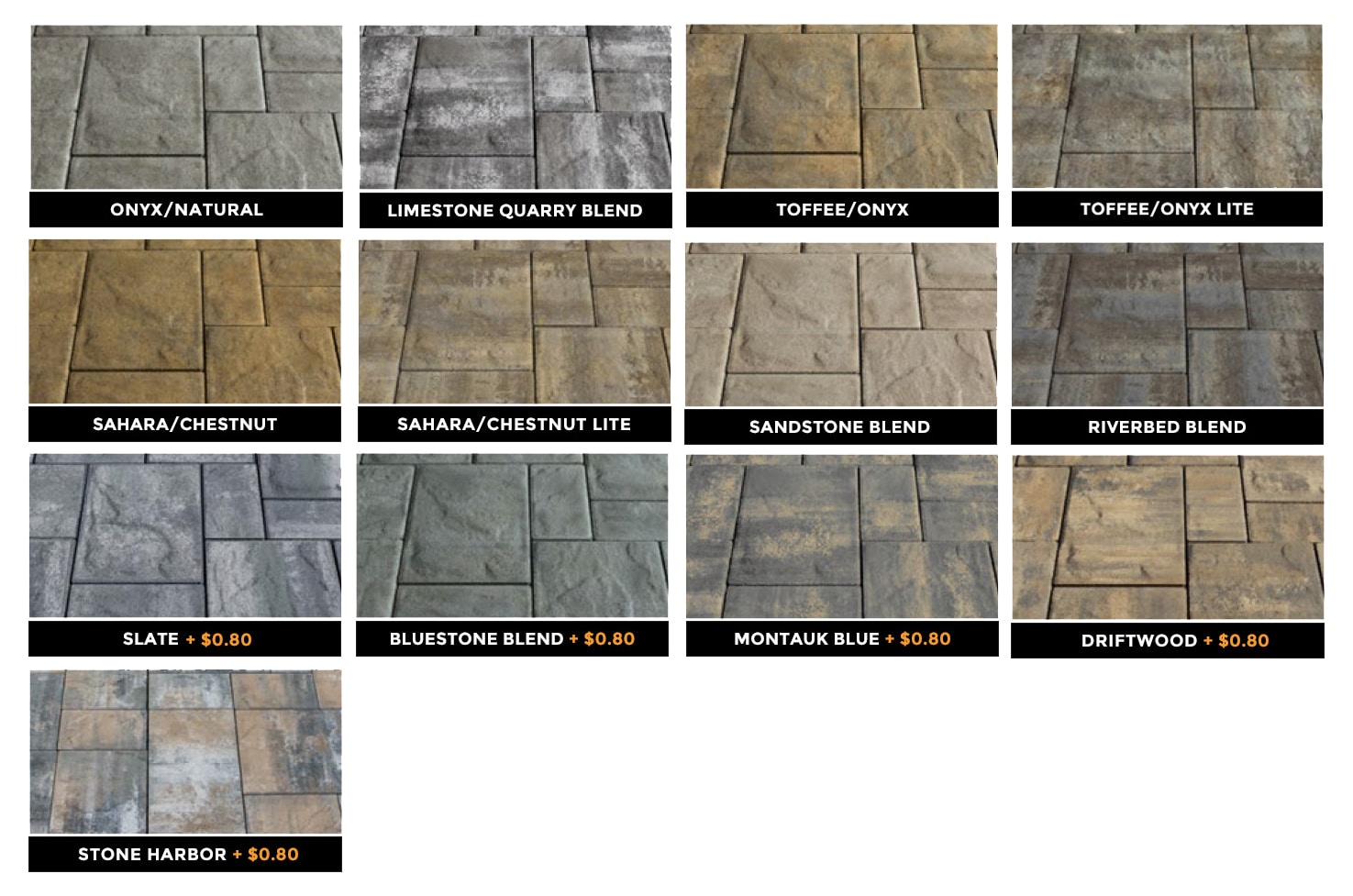

Pavers Included

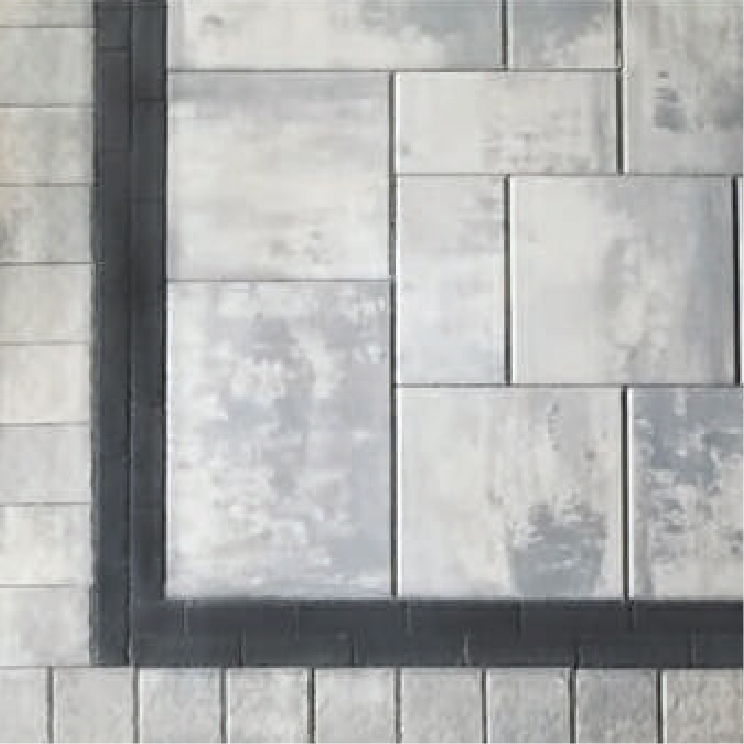

Borders

Single

Matching

Double

Final Stages to Paver Construction

What we do next is add a concrete edge to the perimeter of the walkway that is exposed. This concrete edge is a restraint and keeps the pavers from shifting out of place. The concrete is set about 1 inch below the top of the paver and then gets covered by topsoil. To fill in all the joints between the pavers we use polymeric sand.

This process is where we sweep the sand into the joints and after proper installation and adding water the sand will set to a hard finish. Ultimately locking out weeds and helping keep the pavers together.

Paver Sealants

You may say to yourself you love the way the colors look when the walkway is wet. There are sealers that can leave the pavers with that look.

However, to seal your walkway you will need to wait at least 1 year to seal it. The reason for the wait is to allow the efflorescence to come out of the pavers. You can read about this in another section below.

What AP Customers Are Saying

Ready for Pricing?

Suffolk County’s Premier Patio Installer and Patio Contractors

Affordablepatio.com is Suffolk County’s Premier Patio Installer, patio contractors, retaining wall, fire pit and more. We typically work with Cambridge Paving Stones, but utilize other great materials as well to ensure your patio project turns out the way you want and lasts for many decades to come. All of our patio installations are installed to manufacturer specs, which are provided to you below. The reason we are trusted as a Long Island’s masonry contractor is because we pride ourselves on educating our customers and providing the utmost value to this experience. We have been installing paver patios across Suffolk County for the last 15 years, which amounts to more than 2,000 patios!